Revopac®

Packaging Machinery For Filling

In chemical, food, building materials, new energy, mineral processing and other industries, we have the ability to provide entire line solutions including material handling, weighing, robotic packaging, palletizing, stretch hooding, etc. Moreover, we can customize dedicated systems and ensure high-quality after-sales services for our customers.

Revopac Packaging Technology Co., Ltd (briefly as REVOPAC), located in Shanghai, China, is engaged in the design, development, manufacture, and sales of robotic packaging and palletizing systems. In 2015, the company was acquired by a public company — Shanghai Ailu Package Co., Ltd (stock code: SZ301062). REVOPAC processes cutting-edge packaging technologies in various industries such as chemicals, food, building materials, metallurgy, and minerals. Rather than being just a bagging machine manufacturer, we are a full-line provider capable of delivering complete bagging line solutions, including product conveying, filling, weighing, packaging, palletizing, and stretch-hooding. Moreover, REVOPAC provides tailor-made systems and prompt after-sales service for our customers. Most of the REVOPAC team members come from world-class packaging companies and have overseas working experience. At REVOPAC, we believe that customer experience and benefit are paramount in solution design and implementation. We aim to be a value creator rather than just a solution provider.

Revopac Filling Family

Air Filling System

The air filling system introduces compressed air into the filling chamber to homogenize & fluidize the product and then conveys the product into the bag.

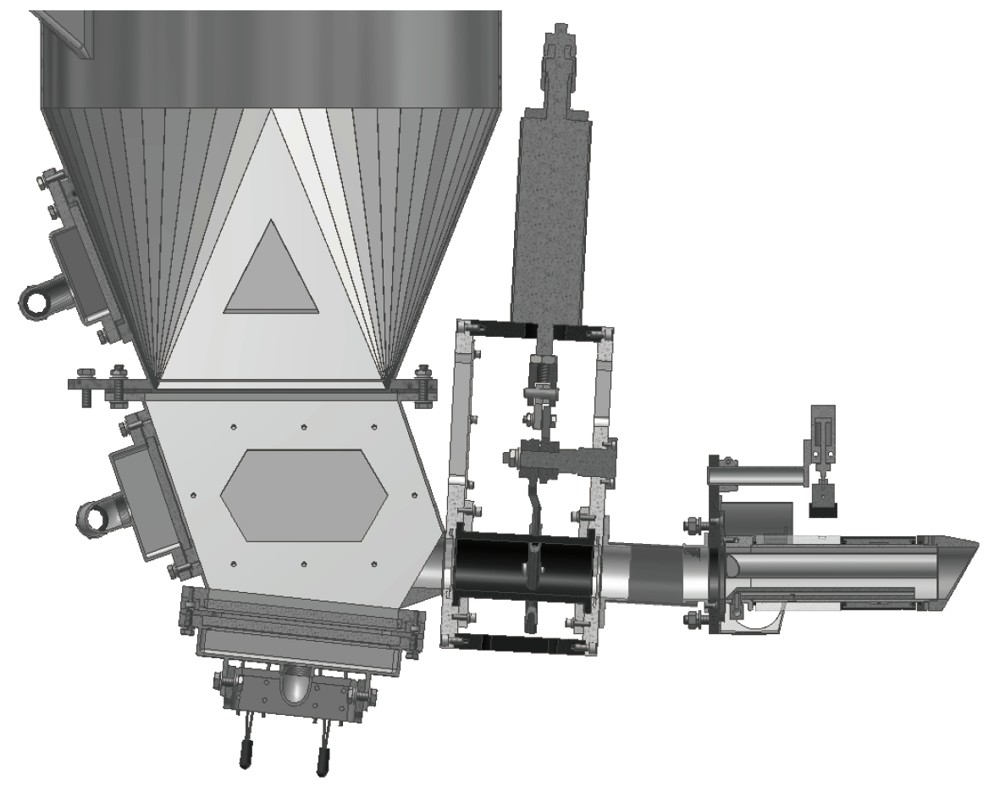

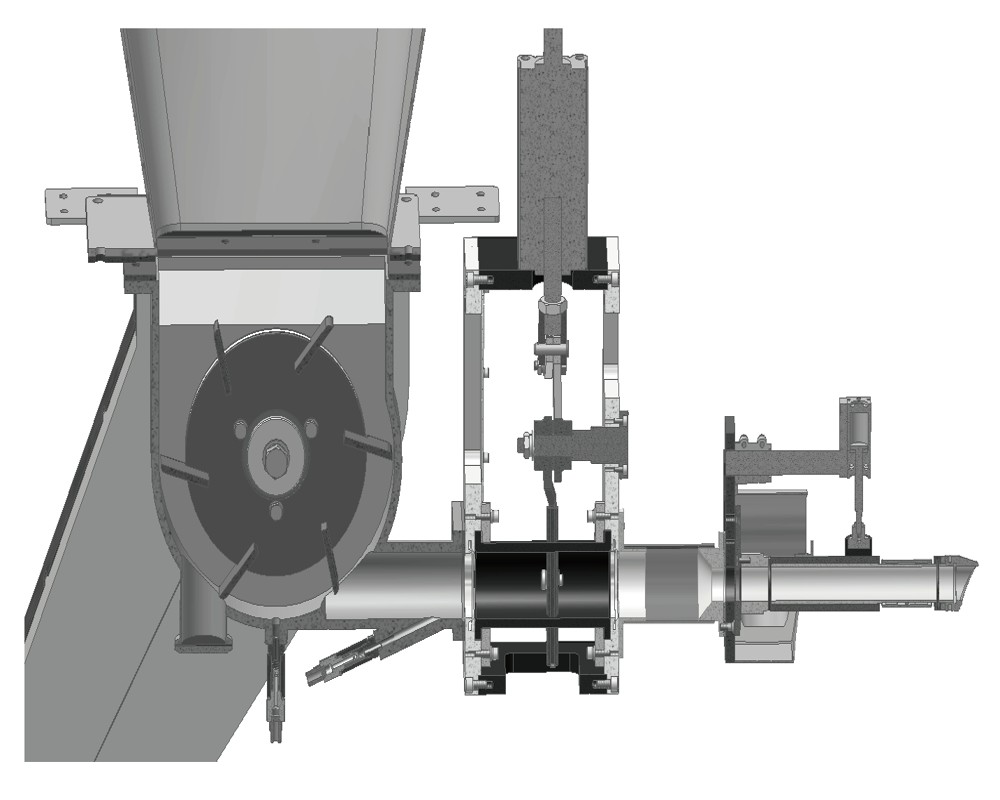

Impeller Filling System

The impeller filling system is specially designed for filling loosefree-flowing or flow-resistant powdery product into the bag.Product filling is realized by an impeller which is driven by a motorwith adjustable speed control.

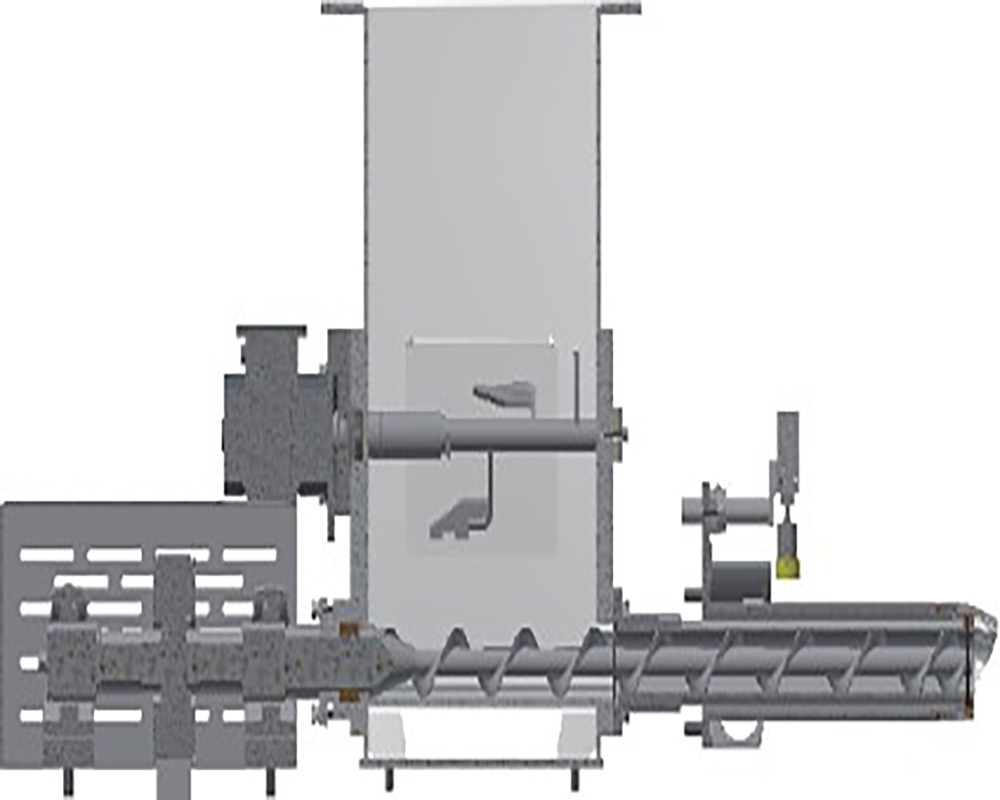

Screw Filling System

The screw filling system is suitable for filling the product with high moisture resistance requirements. Precise product filling is real-ized by the screw which is driven by a motor with adjustablespeed control.

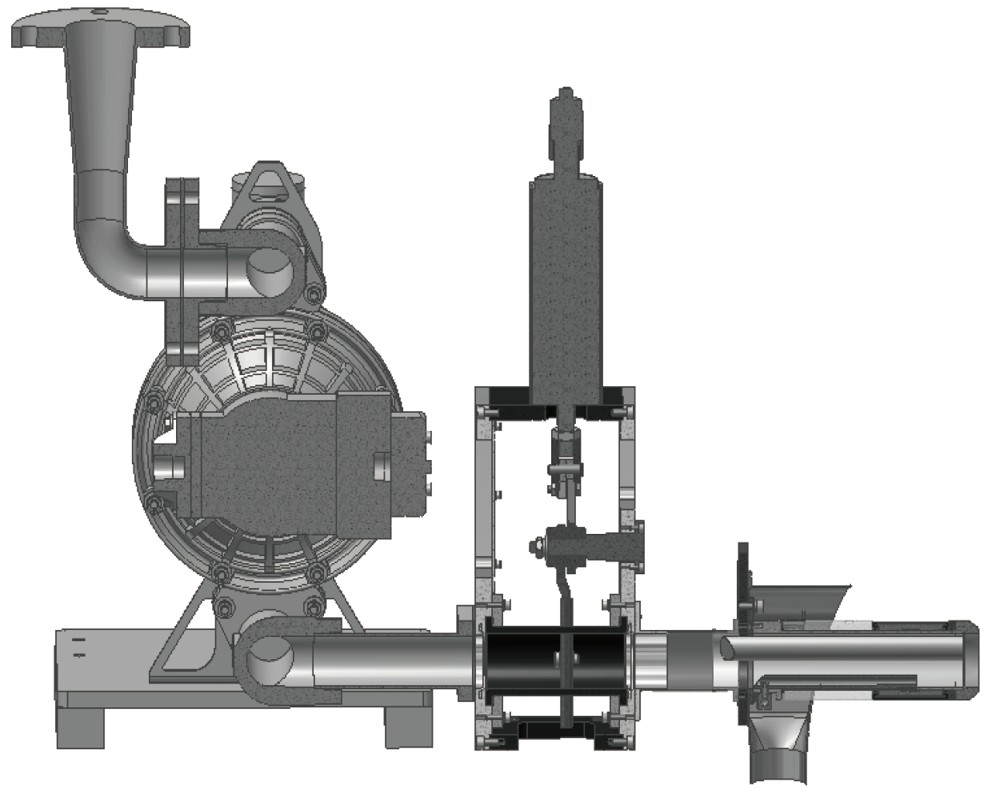

Pump Filling System

Product is introduced into the bag by means of a specially designed powder pump. Compared with traditional vacuum filling system,this design contributes to less energy consumption,higher filling capacity and accuracy.

Valve Bag Packaging Machine

An air filling system is used to fill products with the following product characteristics: free flowing, mealy, powdery and grainy. The product is filled via a hopper into a fluidizing tank and is fluidized by supply air through a permeable mesh. When the dosing unit opens, air conveys the product from the pressure chamber into the bag. The amount of conveying air can be adjusted to the specific type of products.

Open-Mouth Bag Pachaging Machine

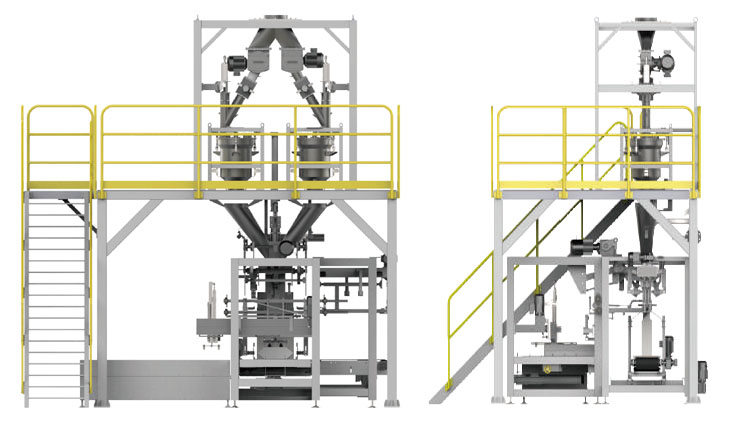

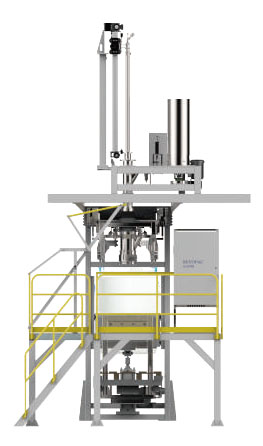

Fibc Packaging Technology

Semi-Automatic

Compared with conventional bags, FIBC represents a more efficient alternative during the transportation of bulk materials. REVOPAC FIBC filling technology can provide customized solutions to satisfy customers’ requirements of all sorts.

Full-Automatic

Compared with semi-automatic machine, full-automatic FIBC packaging machine has a higher level of filling accuracy, and also contributes to reducing labor costs.

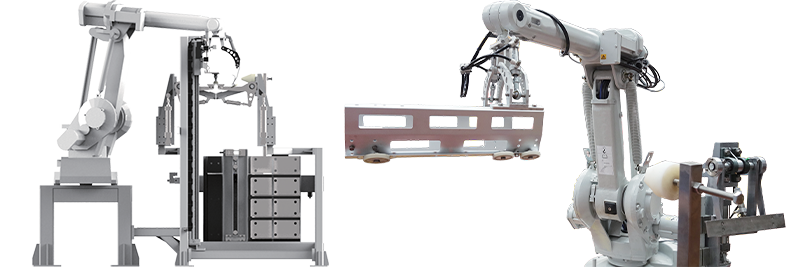

Robotic Bag Placer

Robotic bag placer can automatically place the valve bag onto the filling spout, and is compatible with a variety of bag types.

Mechanical Bag Placer

Compared with robotic bag placer , the mechanical bagging machine has higher stability and simple structure.

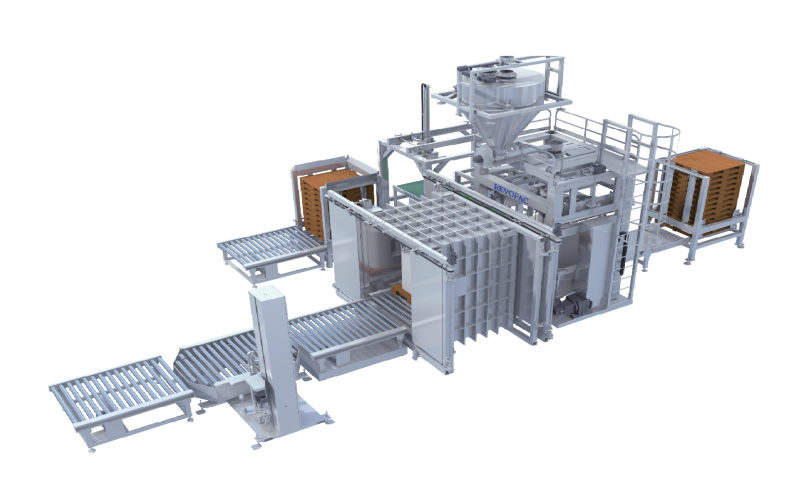

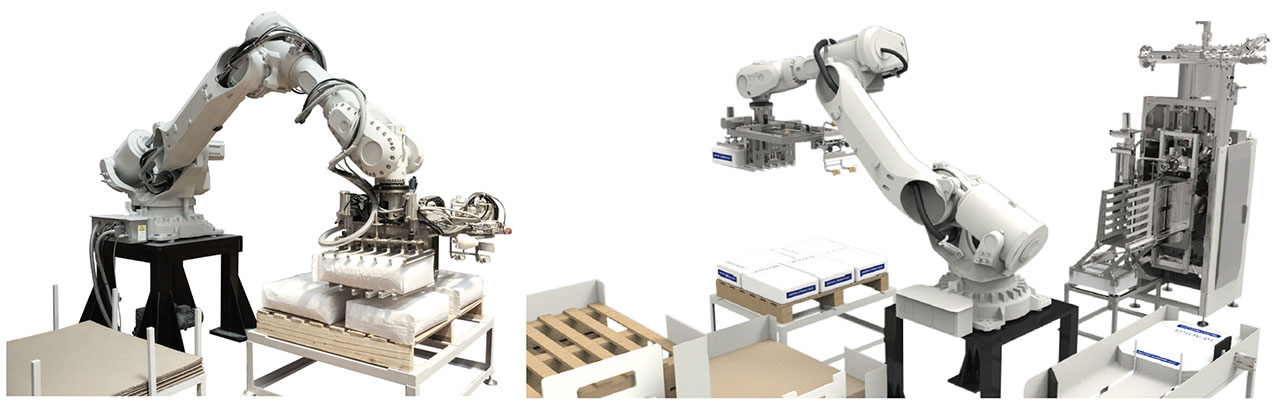

Robotic Bagging & Palletizing System

The integrated robotic valve bag packaging machine providesa unique alternative in dealing with the bagging capacity lower than 120 bags/h. compared with conventional bagging and palletizing line, this system is featured with the following:

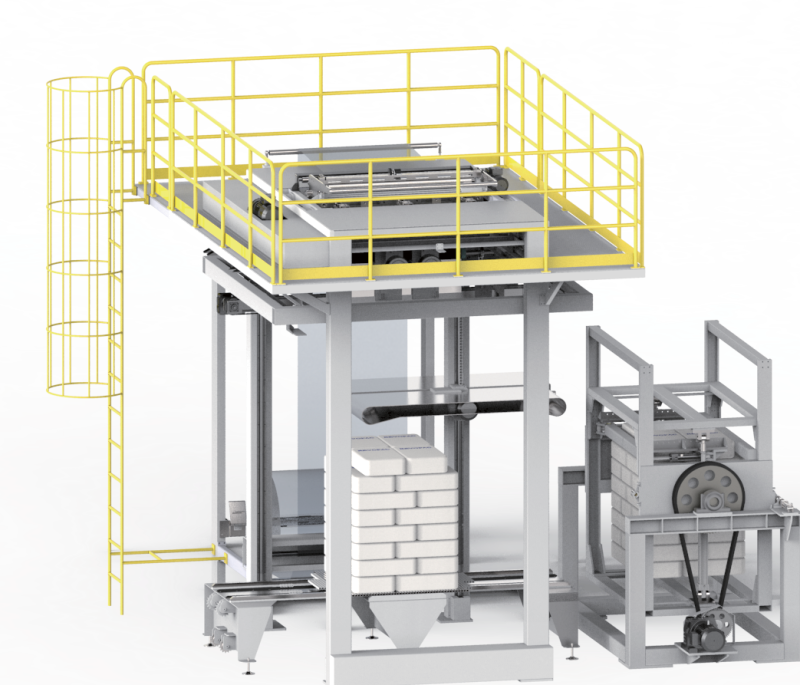

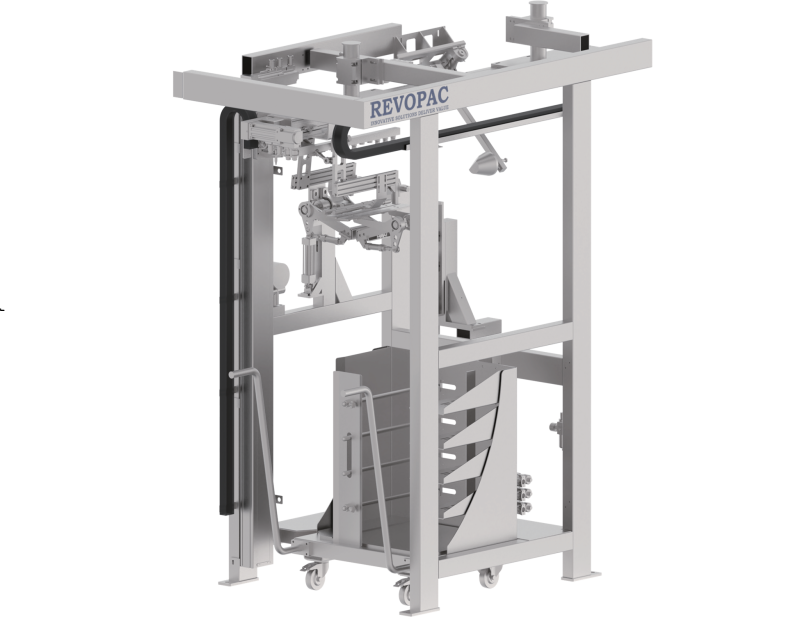

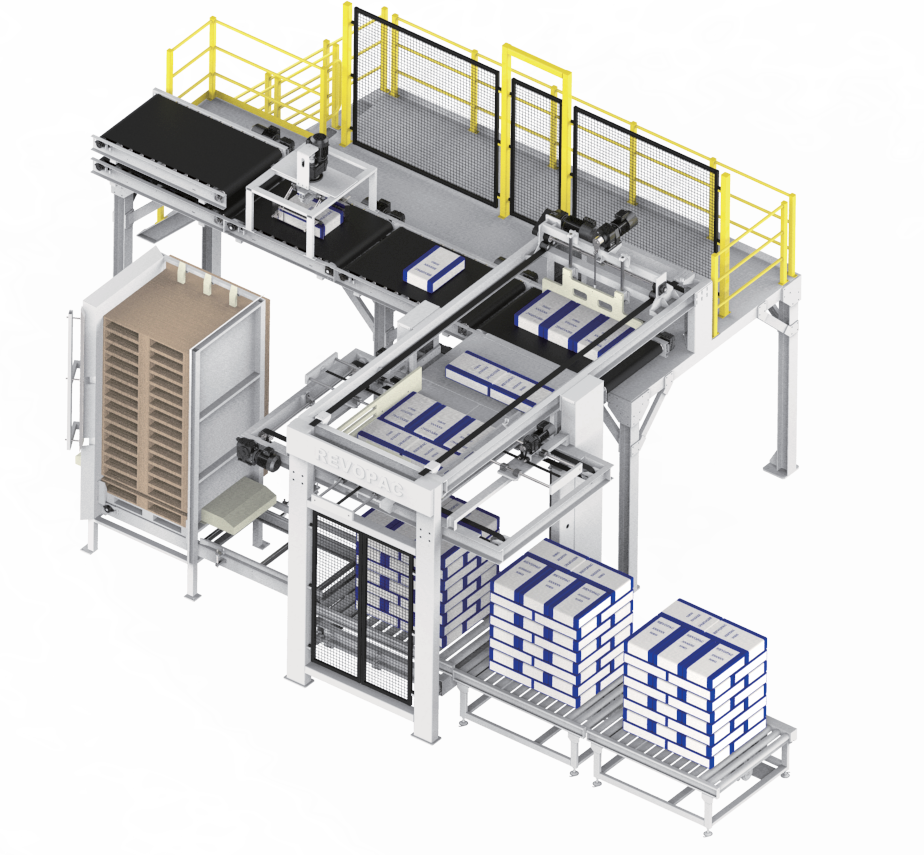

High Level Palletizer

REVOPAC’s high-level palletizer realizes accurate palletizing of packages in bags or bundles as well as cartons. Thanks to its modular design, it’s highly compatible with the layout on-site. It is easy to install and economical in operation and maintenance. In addition, its construction and framework are quite solid, which guarantees long hours of operation with smooth mechanical movement but very little sound.

Palletless Stretch Hood System

The idea that uses the goods themselves as the load platform and eliminates the transport pallet now comes true by REVOPAC Palletless Technology. Compared with conventional pallet loading technology, Palletless packaging proves itself superior in terms of cost, goods protection, and load security etc.