Revopac®

Complete Lines For Filling

Mastery of specialized packaging technology, not only as a manufacturer of packaging machines, but also as an integrator of the entire packaging line.

Revopac Packaging Technology Co., Ltd (briefly as REVOPAC), located in Shanghai, China, is engaged in the design, development, manufacture, and sales of robotic packaging and palletizing systems. In 2015, the company was acquired by a public company — Shanghai Ailu Package Co., Ltd (stock code: SZ301062). REVOPAC processes cutting-edge packaging technologies in various industries such as chemicals, food, building materials, metallurgy, and minerals. Rather than being just a bagging machine manufacturer, we are a full-line provider capable of delivering complete bagging line solutions, including product conveying, filling, weighing, packaging, palletizing, and stretch-hooding. Moreover, REVOPAC provides tailor-made systems and prompt after-sales service for our customers. Most of the REVOPAC team members come from world-class packaging companies and have overseas working experience. At REVOPAC, we believe that customer experience and benefit are paramount in solution design and implementation. We aim to be a value creator rather than just a solution provider.

INNOVATIVE SOLUTIONS DELIVER CUSTOMER VALUE

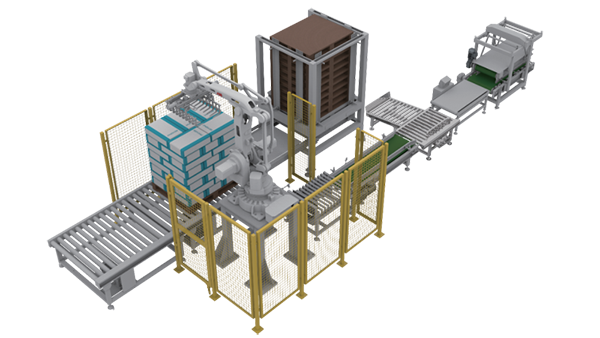

Automatic Valve Bag Packaging Line-Negative Pressure Type

Negative pressure filling, by pumping the chamber into a negative pressure, creates a pressure differential and thus allows the material to be filled into the bag.

REVOPAC’s real-time variable pressure method, which adjusts the appropriate pressure differential with the filling process,

increases the speed and accuracy of negative pressure filling.

Advantages

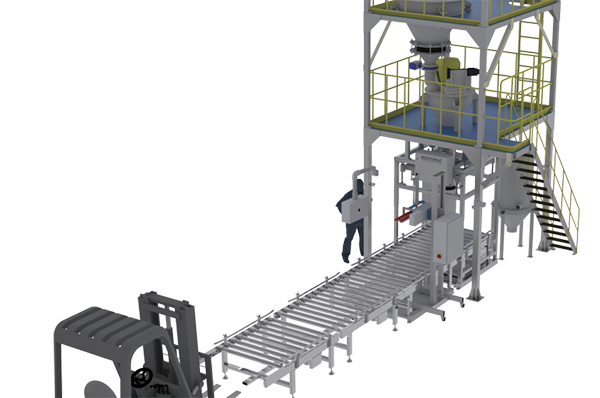

Automatic Fibc Packaging Line – High Precision

Compared with conventional bags, FIBC represents a more efficient alternative during the transportation of bulk materials.

REVOPAC FIBC filling technology can provide customized solutions to satisfy customers’ requirements of all sorts. The high-precision automatic FIBC packaging technology is not only patented, but also awarded as a special project for transformation of high-tech achievements in Shanghai.

Advantages

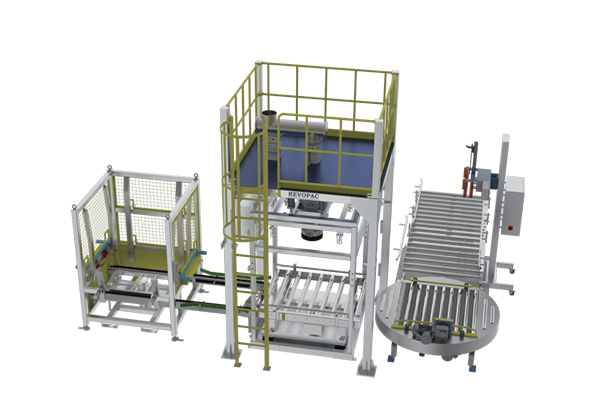

Semi-Automatic Fibc Packaging Line – Vertical Screw Type

REVOPAC’s real-time variable pressure method adjusts the appropriate pressure differential during the filling process. Compared with conventional bags, FIBC offers a more efficient alternative for transporting bulk materials.REVOPAC’s FIBC filling technology provides customized solutions to meet various customer requirements, increasing the speed and accuracy of negative pressure filling.

Advantages

Semi-Automatic Fibc Packaging Line – Viberating Type

Compared with conventional bags, FIBC represents a more efficient alternative during the transportation of bulk materials.

REVOPAC FIBC filling technology can provide customized solutions to satisfy customers’ requirements of all sorts.