Types of Multi-Wall Paper Bag

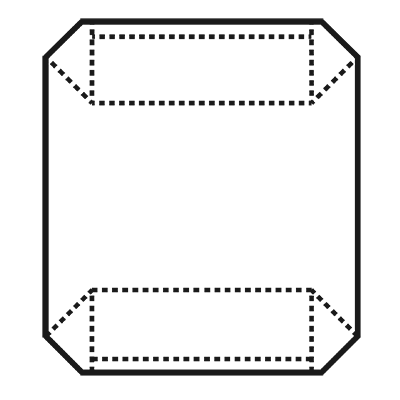

Pasted valve bag

Pasted valve multi-wall paper bag is a prevalent packaging method in the industrial sector designed to package a wide variety of dry flowable products. Pasted valve bags are packed on equipment that deposits material into the bag via a horizontal filling spout. As the bag is released from the packing apparatus, the inherent pressure from the enclosed product causes the valve aperture to autonomously seal shut.

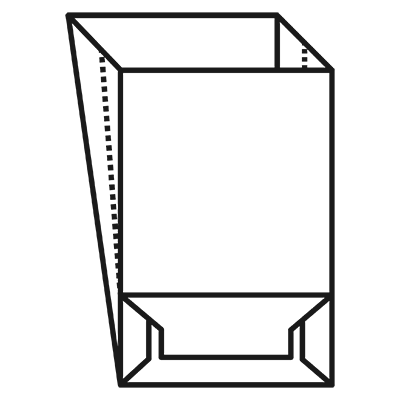

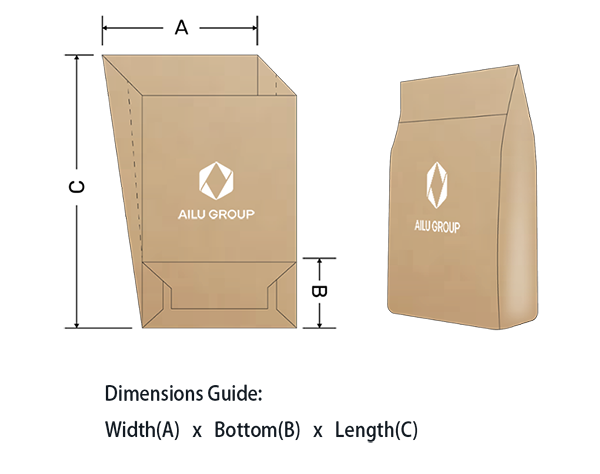

Block Bottom Bag

The Block Bottom bag is available in a multitude of combinations of materials and features. Block Bottom bag is available in coated material, laminated,with free film between the paper plies or with a greaseproof paper barrier. Different external finishes (matte/glossy effect) are available.

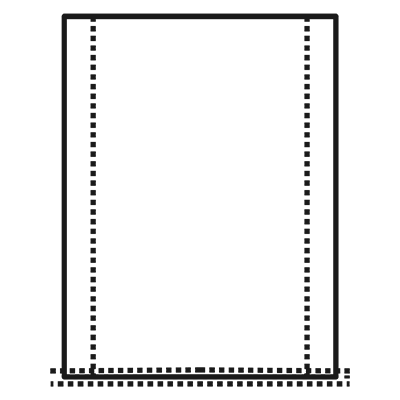

Sewn Open Mouth Bag

Sewn Open Mouth bag is an open mouth bag that is closed using sewing thread. Open mouth bags are packed on equipment that deposits material into the bag via hopper or vertical filling spout. The bottom of the bag is pre-closed by the bag manufacturer. Once the bag is filled, the flush cut open end of the bag is sewn closed by the user.

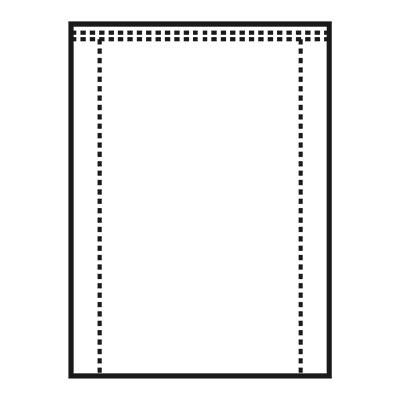

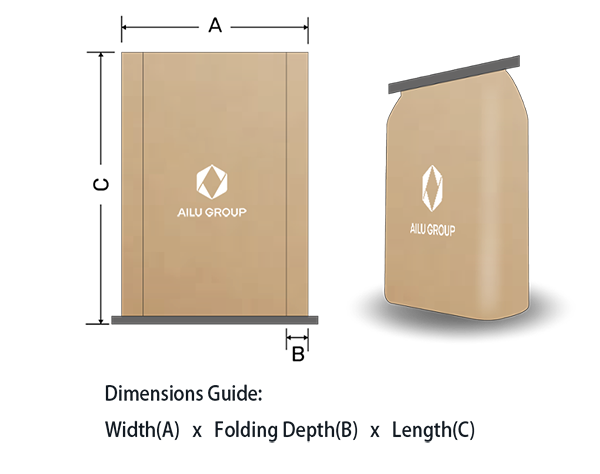

Pinch Bottom Open Mouth Bag

The Pinch Bottom Open Mouth Bag is a popular industrial paper package designed to encapsulate a variety of dry pourable products. The bag features seamless threading, minimal environmental impact, a thorough seal and prevents material caking. Open bags are loaded using a machine that dispenses material into the bag via a hopper or vertical filling nozzle. Once the bag is full, the pinch sealer kicks in and closes the bag by heating air to activate the pre-coated adhesive on the bag opening. This folds the open end for a complete closure and pinches the fold until the adhesive sets. The bag can be supplied with either a stepped finish or a flat top.

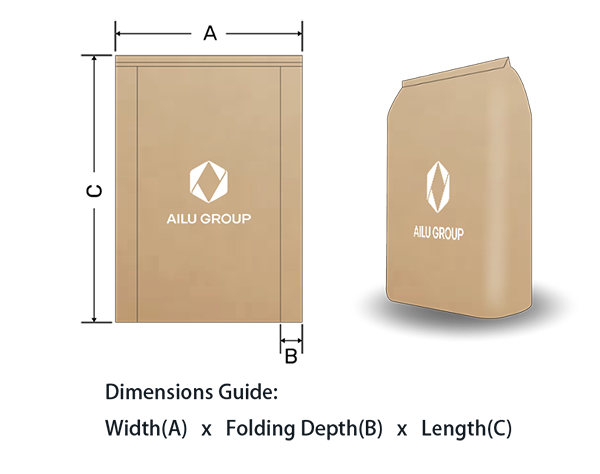

Satchel Bottom Open Mouth Bag

Satchel Bottom Open Mouth (Webb Pinch) Multi-Wall paper bags are a common industrial packaging method.

The satchel bottom open mouth bag is a merger of 2 distinct bag styles (Block Bottom Bag & Pinch Bottom Open Mouth). This unique bag type offers a square satchel style bottom and sealable open mouth top. Satchel bottom open mouth bags are closed/sealed by Pinch Bag Closers using a pre-applied hot-melt to create sift-proof closures. Satchel bottom open mouth bags palletize and handle better than standard PBOM bags due to their square bottom.